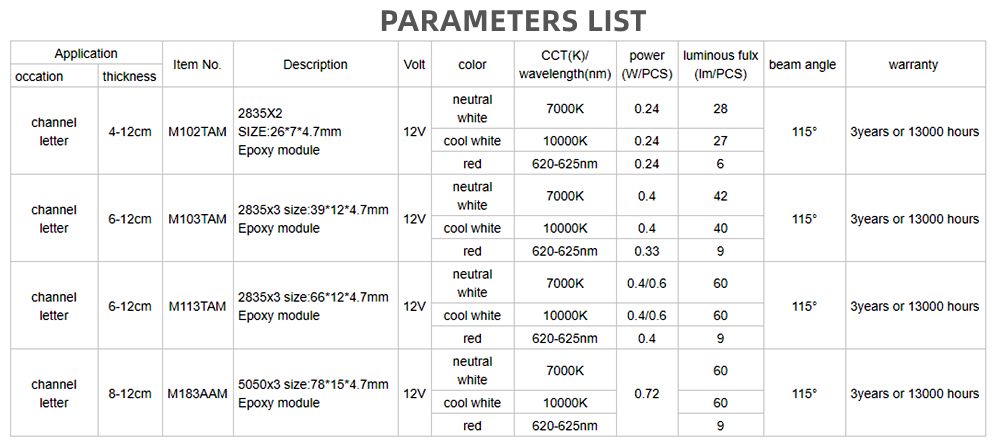

Mini epoxy resin LED sign module light for mini letters, 0.24w 0.4w 0.6w 0.72w

What's the epoxy resin LED sign module light?

Epoxy resin LED sign modules are a type of lighting system that uses LED lights embedded in an epoxy resin material to create bright, durable, and visually appealing signs. The epoxy resin material is a type of thermosetting plastic that hardens when cured, resulting in a strong and durable material that can withstand exposure to the elements and the passage of time.

LED sign modules are small, self-contained lighting units that can be arranged in different configurations to create various shapes and sizes of signs. The LED lights are energy-efficient, long-lasting, and emit a bright, even light that is ideal for illuminating signs. The epoxy resin material encapsulates the LED lights, protecting them from damage and ensuring a long lifespan.

One of the key benefits of epoxy resin LED sign modules is their ability to create eye-catching visual effects. The transparent resin material can be colored, and the LED lights can be programmed to change colors or pulse at different intervals, creating a dynamic and engaging display. This makes epoxy resin LED sign modules an ideal choice for businesses looking to attract attention and create a memorable brand identity.

Features:

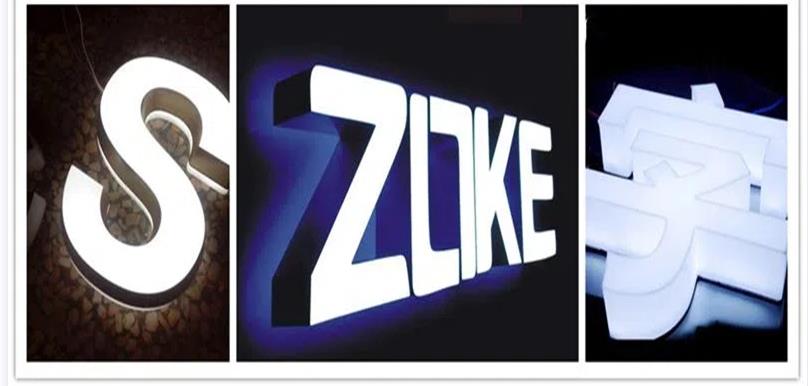

Epoxy resin LED sign modules can be used for a wide range of applications, including outdoor signs, indoor signs, architectural lighting, and decorative lighting. The modules come in different shapes, sizes, and colors, allowing for a high degree of flexibility in sign design. They are also easy to install and maintain, making them a popular choice for both commercial and residential applications.

§ LED module light used usually for Billboard, Signage and illuminated advertising. And also as the Backlighting of channel letters and light box

§ No light spot, low light decay, good consistency;low power consumption, no dark area, ensure the illuminous effect and performance

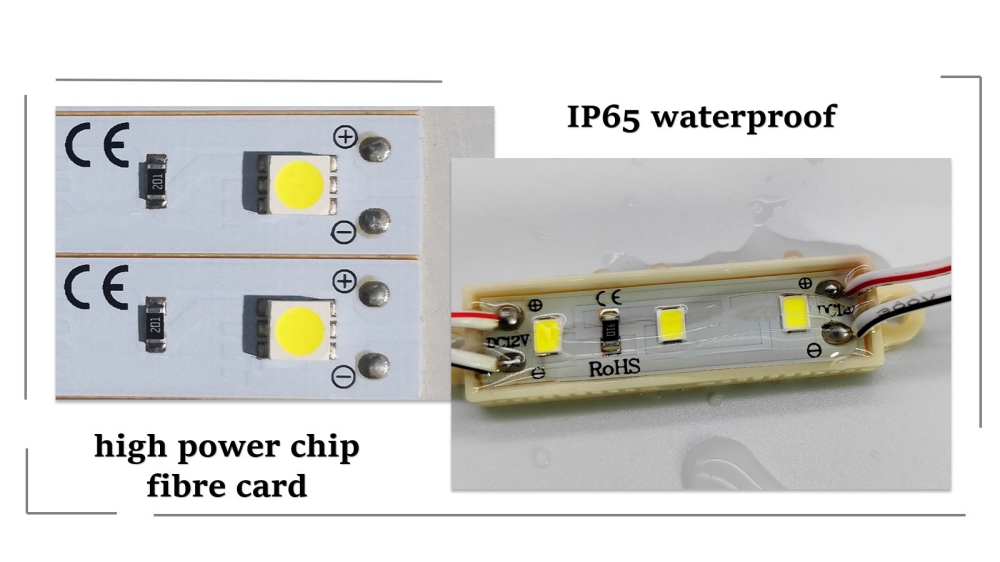

§ DC12V low voltage input, safe and reliable for use, waterproof grade up to IP65;

§ The 20pcs modules in one string, constant voltage design to ensure its steady when working

§ Please note all the installation would be conducted by experienced or technician

§ High power output or lumen don't means high quality. We should consider its light decay, heat dissipation,and chips life span.... our engineer just give you the right LED product under scientific design assure 3years or 5years warranty.

§ No matter AC or DC output, all the module light can work only connect with right power supply or adaptor. Please refer to our sales or our accessories link

what's the difference bwtween the epoxy resin LED signs moduel and injection LED signs module?

epoxy resin LED sign modules and injection LED sign modules are two different types of lighting systems used in creating illuminated signs. While they share some similarities, there are also some key differences between the two.

Epoxy resin LED sign modules, as previously discussed, consist of LED lights embedded in an epoxy resin material. The LED lights are encapsulated in the transparent resin, which provides protection from the elements and creates a durable and long-lasting sign. Epoxy resin LED sign modules are flexible, can be customized in terms of shape and size, and can create visually engaging lighting effects.

Injection LED sign modules, on the other hand, use a different method to encapsulate the LED lights. Instead of epoxy resin, injection LED sign modules use a plastic injection molding process to encapsulate the LED lights. The LED lights are placed inside a mold, and molten plastic is injected into the mold to create a solid module. The resulting module is then trimmed and tested before being assembled into a sign.

One key difference between the two is the production process. Epoxy resin LED sign modules are made by pouring resin into a mold that contains the LED lights, while injection LED sign modules are made by injecting molten plastic into a mold that contains the LED lights. This means that the manufacturing process for injection modules is faster and more efficient, while the process for epoxy resin modules is more labor-intensive.

Another difference is in terms of flexibility. While epoxy resin LED sign modules can be customized in terms of shape and size, injection LED sign modules are more limited in their flexibility due to the molding process. Injection modules are usually produced in standard shapes and sizes, and customization options may be more limited.

In summary, both epoxy resin LED sign modules and injection LED sign modules are effective lighting systems for creating illuminated signs. The choice between the two will depend on factors such as production time, customization options, and the specific needs of the project.

Welcome to consult DELIKAY , the supplier of epoxy resin LED sign module light!

OEM customized service &Turn-key solution available!