In 2024, the channel letter sign market is in a period of rapid development, with the market size continuously expanding, technology constantly innovating, and the industry development trend being favorable. The channel letter sign technology is constantly advancing, from neon lights to LED lights, to the application of OLED technology, each technological upgrade is driving the industry forward. The LED light, with its advantages of low energy consumption, long lifespan, and rich colors, has become one of the widely used light sources for signs. Modern control systems can achieve precise control of signs, providing greater space for the creative expressiveness and functionality . At the same time, with the increasing awareness of environmental protection, the energy consumption and light pollution of signs have attracted widespread attention. The industry is facing the challenge that reducing energy consumption and light pollution while maintaining its aesthetic value at the same time.

With the acceleration of urbanization, channel letter signs are becoming increasingly important in urban construction. They not only convey commercial information, but also create a unique landscape in the city, becoming a display of urban art. LED signs are the highlights of commercial lighting environments, but when they no longer light up,or other damages occurred, they will affect the brand image of and value.

Here are the current market pain points and solutions for LED signs:

1: The entire circuit is broken

When the entire LED sign is not lighting up, please check the LED power supply (transformer) firstly. Because it is the key component that provides a stable voltage and current to the LED lamp beads. If the power supply malfunctions, the entire LED sign will not work. In that case, please replace the detective power supply with a new one.

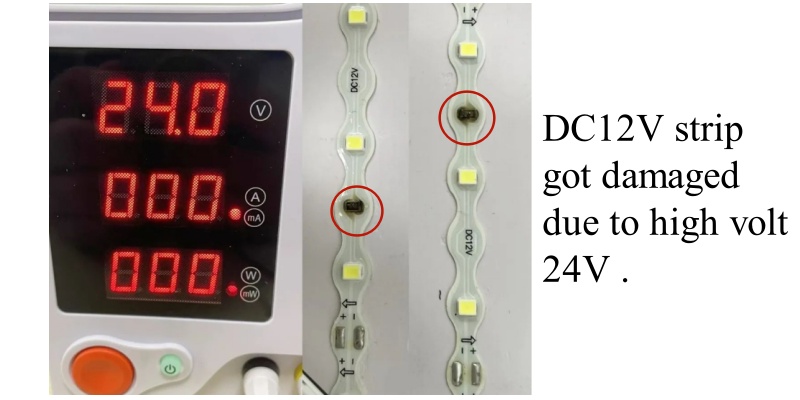

Check the LED beads: if the LED sign is not working during installation, it may be connected directly to the 220V, the beads are burn out. In this case, please replace the whole LED lighting source;

Check circuit connection: The loose or poor connection may also cause broken circuit and make the entire LED signs don’t work. So please check it again.

Check the circuit damage: The circuit may be interrupted due to environmental factors, such as rat bite, etc. Make the necessary repair or replacement;

Check the LED lighting source: There may be a problem with the LED lighting source If part or the whole signs is not working . Need to check whether the lighting source receives the appropriate voltage and current, and ensure that the source is not damaged;

Heat dissipation problem: Heat dissipation will also affect its normal operation. If the heat dissipation is poor, it may cause the LED overheating, which can affect the luminous effect or cause damage.

2: Part of LED signs don’t light up

Poor or loose connecting : This situation usually occurs at the connection point due to vibration, aging, or improper installation problems. Addressing this requires rewiring and ensuring that all connections are firm and reliable.

LED bead damage: It is possible that individual LED beads damage that causes the whole series of beads to not light up. In this case, replace damaged beads . Each LED bead is independent and can be replaced separately, which requires experienced technician to cover it.

Heat dissipation problem: LED beads will generate heat when working, if the heat dissipation is bad, it will cause the beads to overheating, and then affect its performance and life. Ensure that the LED lamp beads have good heat dissipation conditions, which can extend their service life and maintain their brightness

Power supply: If the power supply of the lighting source is unstable or insufficient, it may also cause some of the beads not bright. Check the power supply is sufficient or loose connecting.

Environmental factors: When the LED signs is worked outdoors, it may be affected by environmental factors, such as humidity and temperature changes, which may affect the performance of luminous characters. Ensuring good waterproof performance, as well as regular inspection and maintenance, can reduce the occurrence of such problems.

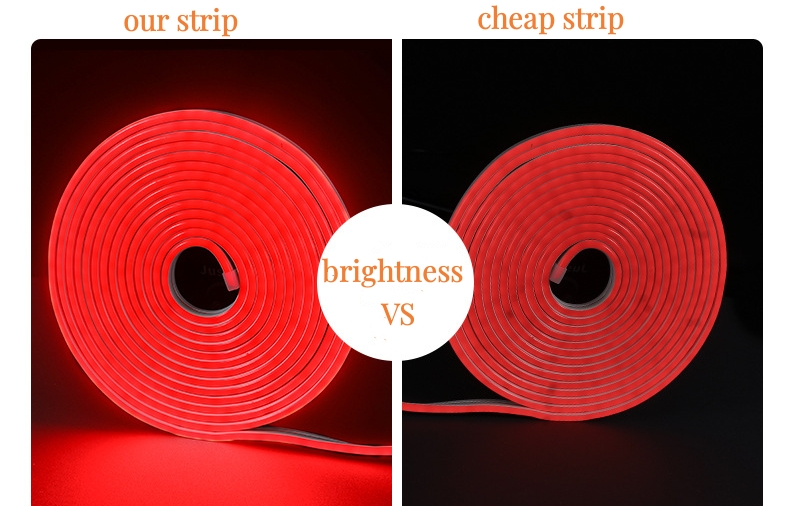

3:LED sign is in low brightness

Lamp bead quality problem: If the LED sign look dark, maybe it is low lumen LED chips. Different brands and quality of LED beads have different lumen even based on same specification. Therefore, the selection of well-known brands and high-quality LED beads is crucial to ensure the brightness and life of the signs.

Installation damage: During the installation process, if the PCB is damaged, it may also lead to the dark or shade area.

Metal contact problem: If another end of a group of LED beads touches the metal, increasing the resistance, it will reduces the current through the beads. This situation is particularly common in large outdoor channel letter signs, so please pay attention the connecting problem and avoid the voltage problem. Do remember feed power in those very long serial connecting.

Power supply: Please use the sufficient power supply. We advise only take up 80% volume of rated power for the sake of longer working life.

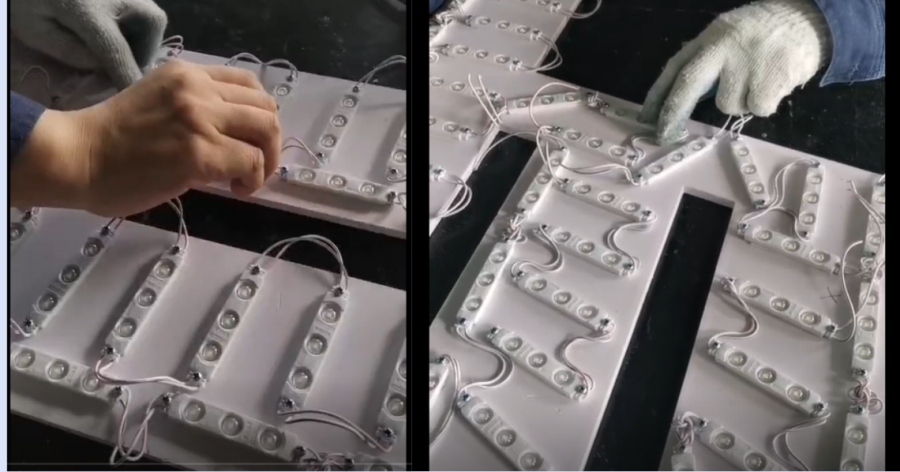

How to replace or maintain the LED signs?

Firstly figure out where the problem is: It is necessary to accurately find out which LED beads or which part of the PCB get damaged. This can be done by visual inspection or by using specialized testing equipment under the conduct of professional technician.

Prepare tools and related accessory: Prepare necessary tools such as hot welding pads, solder wire, flux, tweezers, etc., and new LED beads that match the original bead specifications.

Safe operation: Make sure the power is disconnected to avoid electric shock. At the same time, ensure that the operating environment is clean and dust-free, so as to avoid dust pollution of the lamp beads.

Remove damaged beads: Remove the defective LED beads using tweezers or diagonal pliers carefully. During which process, be careful not to damage other electronic components.

Clean the solder pad: dissolve the original residual solder with the flux to ensure that the new LED beads can be welded more firmly.

Install the new bead: Place the new LED bead on the original pad position and ensure smooth alignment with the original solder joint. Heat and weld using a solder wire and remove excess solder or residue.

Test new beads: Use a multi -meter to test the voltage and current of new LED beads. After confirmation, light up the whole fitting for testing to ensure that the new beads work properly.

Reassembly: After the test, reassemble the glow words and inspect visually to ensure no damage or defects.

Comprehensive test: After completing the repair, start comprehensive lighting test to ensure that the entire signs work normally and emitting uniform and evenly

Maintenance and Prevention: To reduce future maintenance requirements, regular inspection and maintenance checks are needed, including dust cleaning, checking connection stability, and ensuring stable power supply. Choosing established brands and high quality LED beads can reduce maintenance rates, thereby reducing maintenance costs and improving reliability. It will be more cost-effective in long terms run.

Finally in a conclusion, Please choose a stable, reliable, long-term sustainable supplier . Especially the continuous supplying of the lighting source, it will ensure the stable lighting effect in different production batch. It is crucial for those chain-yard.