Factory wholelesale High voltage AC110V 220V waterproof COB led light strip

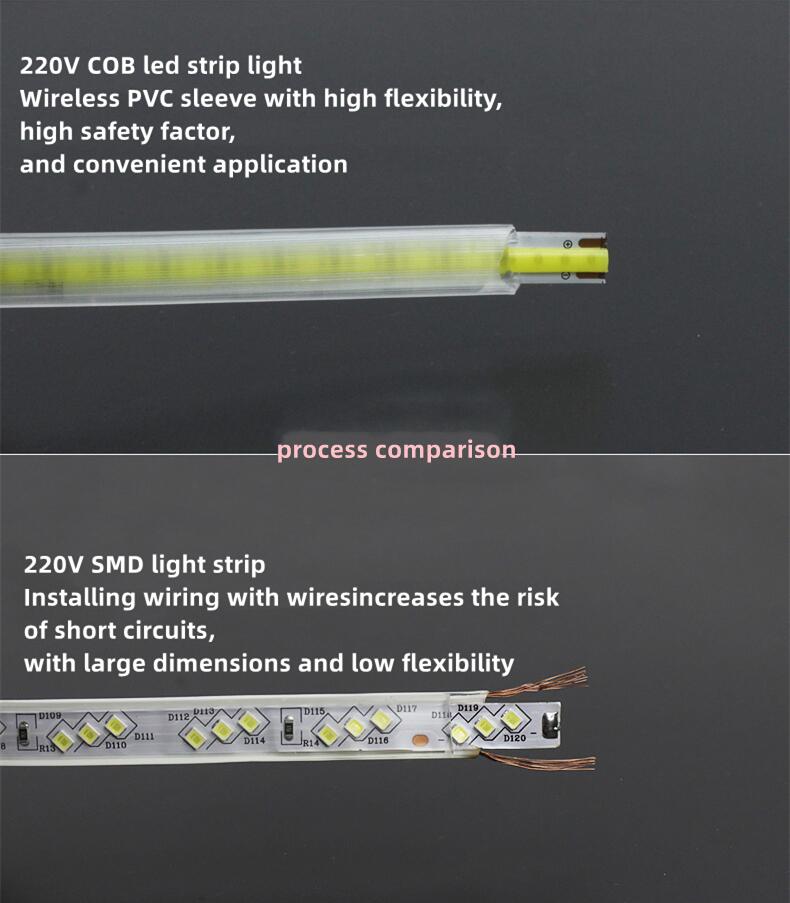

The difference between high voltage COB light strip and ordinary patch light strip?

COB (chip on board) LED technology has revolutionized lighting and has become a popular choice for many lighting applications. High-voltage COB light strips and ordinary patch light strips are two different types of LED light strips with distinct features and applications.

The High-voltage COB light strip is a type of LED strip that uses a high-voltage chip, which is integrated directly onto the circuit board. This technology allows the LED to emit a more intense and concentrated light that is brighter than traditional LED strips. The high-voltage COB light strips are also known for their excellent color rendering capabilities, allowing them to render colors more accurately than other LED light strips.

Another significant advantage of high-voltage COB light strips is that they are more energy-efficient compared to traditional LED strips. This is because they generate less heat and consume less energy while providing a higher light output. Due to their efficiency, they also generate less heat, which makes them more reliable and longer-lasting.

On the other hand, ordinary patch light strips, also known as SMD (surface-mounted device) LED strips, are a traditional type of LED strips that are commonly used in residential settings. The ordinary patch light strips use small LED chips mounted on the surface of the strip, which are connected to the circuit board.

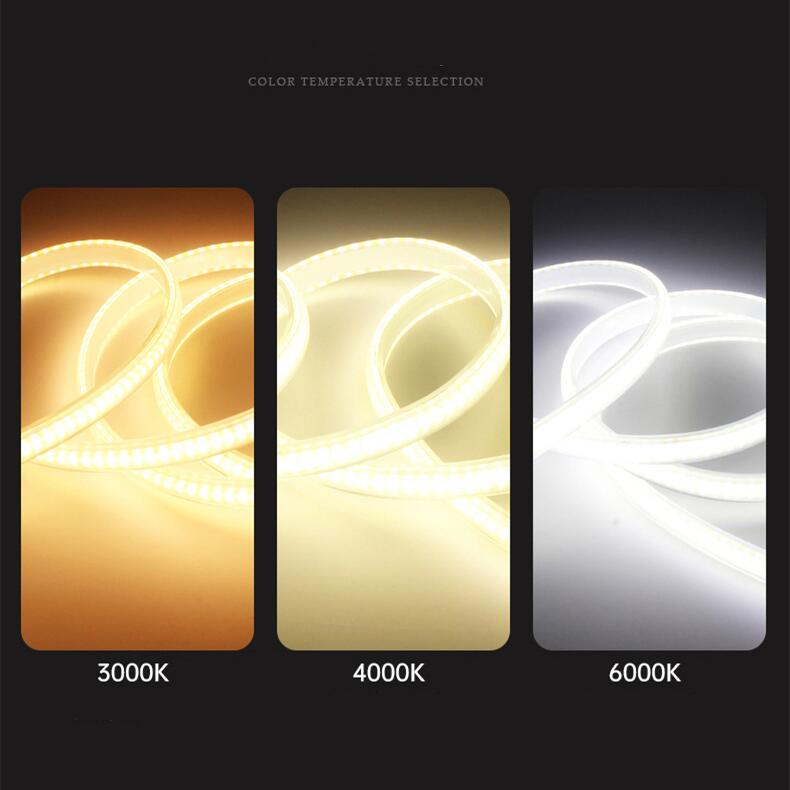

Unlike the COB technology, ordinary patch light strips have a lower intensity and are less bright. They are, however, more versatile compared to COB strips, providing a wide range of color temperatures that make them suitable for a variety of lighting applications.

In terms of installation, high-voltage COB light strips require high precision and skilled handling during installation. This is because they have a higher density of LEDs, and any damages to the intricate soldering or the chips can affect the light output and the lifespan of the LEDs.

Ordinary patch light strips, on the other hand, have fewer LEDs and are less challenging to install. They are more flexible and easy to cut, enabling customization for different lighting needs in various settings.

Lastly, the price of high-voltage COB light strips is higher compared to ordinary patch light strips. This is because they are more technologically advanced and offer better lighting quality and efficiency. As such, they are commonly used in high-end applications such as architectural lighting, where a high level of light output and color rendering accuracy is required.

In conclusion, high-voltage COB light strips and ordinary patch light strips each have distinct features and applications. The suitability of each of these LED strip lights depends on the intended application, the lighting requirements, and the available budget. Therefore, it is essential to consider these factors before selecting the appropriate LED strip light for any lighting project.

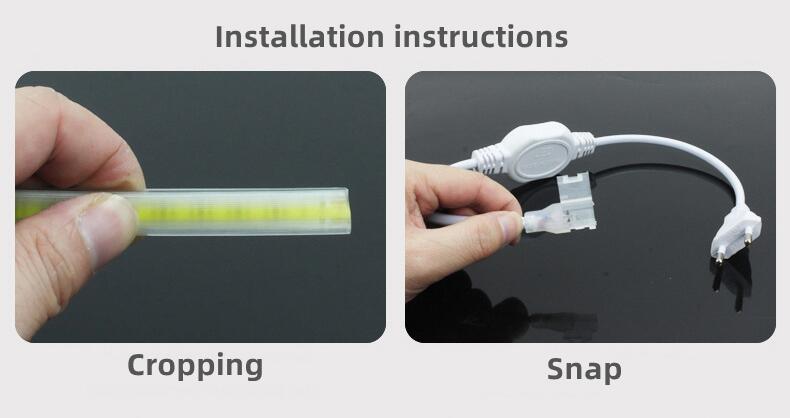

What are the requirements for high voltage led strip light installation ?

Installing high-voltage LED strip lights requires certain requirements to ensure the safety and proper functioning of the lights. Here are some of the common requirements for high-voltage LED strip light installation:

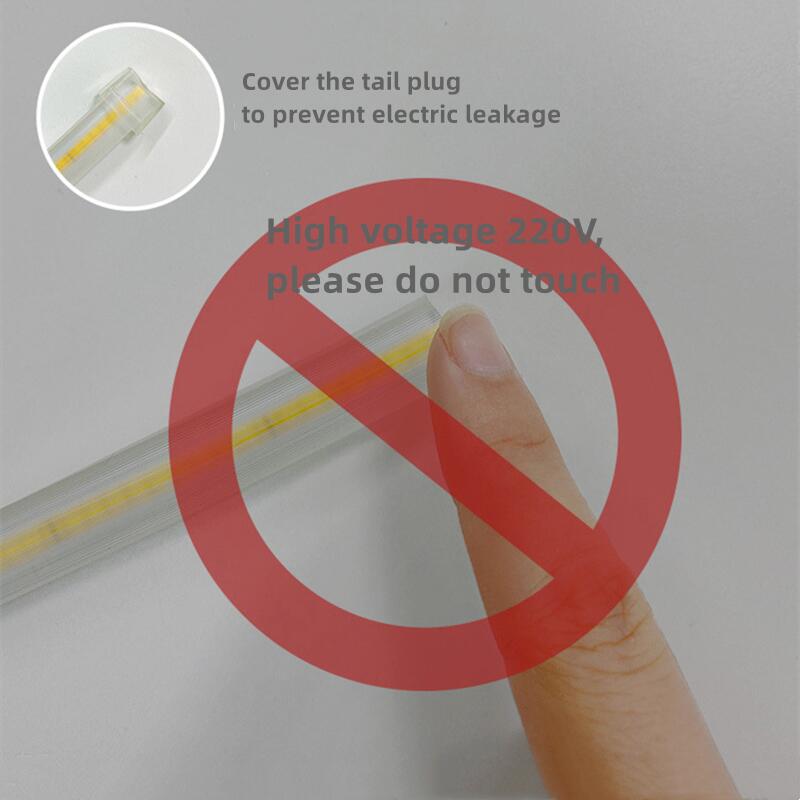

1. Electrical Knowledge - One of the primary requirements for installing high-voltage LED strip lights is electrical knowledge. You should have basic electrical knowledge and understand how to wire the lights.

2. Power source - The LED strip lights power source should provide the accurate voltage and amperage rating based on the length of the LED strip lights required. You can run the high voltage LED strip lights with an AC power source or a low voltage DC transformer.

3. Power Cables - The power cable connecting between the power source and the high-voltage LED strip light should be capable of handling high voltage especially if the LED strip lights will be used in outdoor areas or high-traffic areas.

4. LED strip lights - LED strip lights come in a variety of colors and brightness levels. It is important to choose the right LED strip lights for your project and ensure that they are high-voltage and suitable to your project needs.

5. Mounting - The high-voltage LED strip lights should be mounted using appropriate clips, screws, or adhesive tapes onto the surface.

6. Wiring Connectors and Extensions - You may require wiring connectors and extensions to attach the LED strip lights and provide electrical power to the right areas.

7. Power Supply Enclosure - It is important to ensure that the power supply enclosure used to power the LED strip lights is made from a non-conductive and waterproof material to avoid any accidents.

8. Electrical regulations - Before installing high-voltage LED strip lights, it is important to research and follow any electrical regulations applicable to your specific location.

In conclusion, installing high-voltage LED strip lights requires careful consideration of various factors and fundamental knowledge. This will help guarantee the safety and longevity of the LED strip lights. Therefore, seek the help of a certified electrician if you are unsure of the wiring and installation process.

Welcome to consult DELIKAY High voltage AC110V 220V waterproof COB led light strip!

OEM customized service &Turn-key solution available!