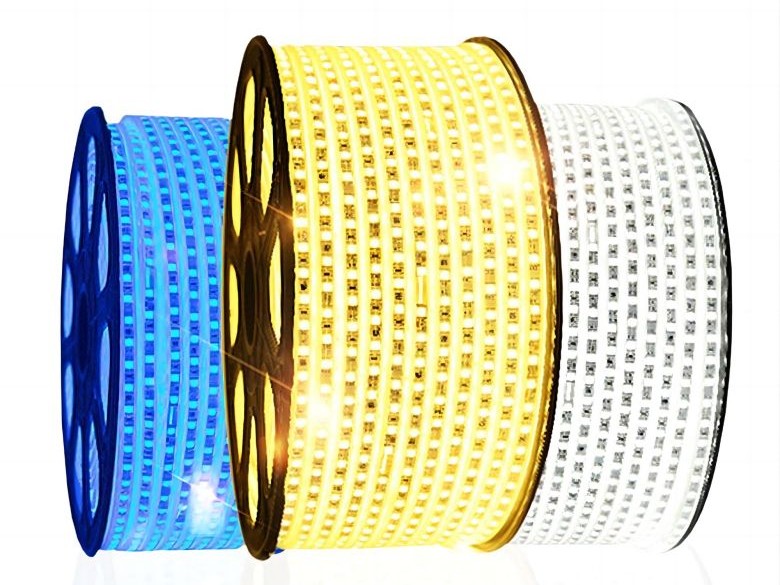

25m/Reel 50m/Reel 100m/Reel OEM Flexible High voltage AC220V IP67 outdoor LED strip lights Used in Swimming Pool lighting project huge lighting display

Whether it is commercial lighting or engineering lighting, light strip is one of the most commonly used lamps, with the main function as ambient lighting, and also be basic lighting.

Usually the light strips are divided into high voltage and low voltage.

And what is High voltage AC220V IP67 outdoor LED strip lights ?

The so-called high-voltage light strip is that can input 220V utility power directly. Generally, it varies from 50 meters /roll or 100 meters / roll with fully PVC tube housing , which can be cut by 100cm,50cm ,even10cm at will. and with a power supply plug be connected to the utility power for normal use. The structure inside this plug head a diode rectifier inside, which rectifies the AC power into DC . Because LEDs are semiconductors and need direct current to work normally. Generally, the rated current setting of the diode rectifier cannot be exceeded, otherwise it is easy to burn out.

Main components of the light strip:

1.light source: 2835, 5050, 5730,etc

Light color: single,dual color, RGB,etc

Specifications: single row, double row, oblique three row, 48 leds, 60 leds, 96 leds, 120 leds,etc

2.Flexible PCB

The most important part, is the flexible circuit board(FPC) .we know, a single LED bead is about 3-5V; then more than 60 beads string up, the total voltage can be about 200V,very close to the utility power voltage 220V. It can work normally after connecting the diode rectifier with the right current controlled by the resistor .sometimes it can also get more than 60 beads string together, like 90, or 120leds, just in parallel connection. the length is also close to one meter. Therefore, the high voltage strip light is generally a meter for a cut.

The quality requirement of the flexible circuit board is to ensure the current load within one meter. Because of single series of current is generally based on milliampere level, unlike the DC strip light, it has lower requirements on the copper thickness , and single layer PCB is common used actually.

Conductor wires

What connects each section of light strip is the conductor wire. It loads high-voltage direct current, and the voltage drop is very small compared to 12V or 24V low-voltage lamps. This is why high-voltage light strips can be rolled 50 meters, or even 100 meters. The wires embedded on both sides of the high-voltage light strip are transmitted the electricity to each section of PCB.

So,the quality of the conductor wires are very important for the entire high-voltage strip light. Generally, the high-quality high-voltage light strip wire is made of pure copper wire, and the cross-sectional area will be relatively thick, which can load the total power of the high-voltage light strip.

But cheap and low-quality one will not take copper wire, but copper-clad aluminum wire, or aluminum wire, or even iron wire. The brightness and power of this light strip will naturally not be very high, and with higher probability of the wire burning out caused by overload . It is recommended that avoid buying such light strips.

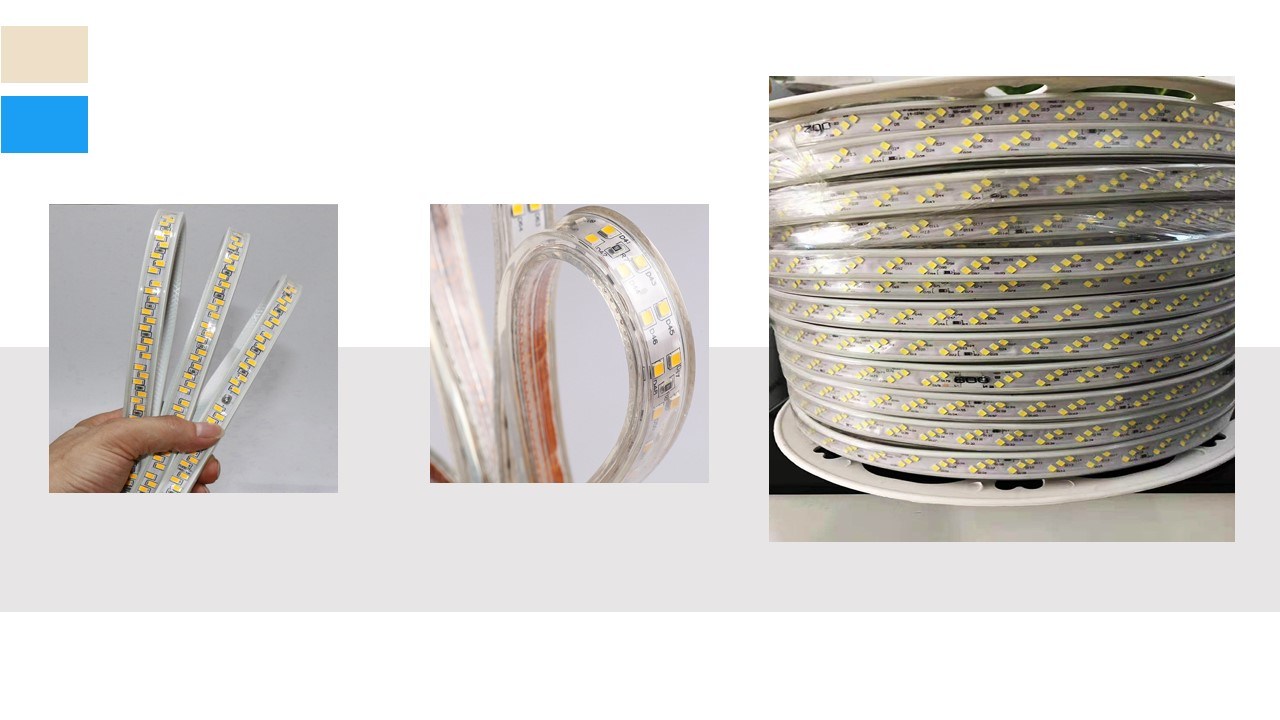

3.Package housing materials

The high-voltage light strip runs high-voltage electricity, which will be dangerous and the insulation work is a must . The common method is to pot transparent plastic made of PVC housing.

This plastic has good light transmission, light weight, good plasticity, insulation, and thermal insulation performance. With this layer of protection, the high-voltage light strip can be used safely, even outdoors in the wind and rain.

DELIKAY can even provide suitable PVC materials depend on local regional weather conditions. For example, in the alpine regions of Eastern Europe, the cold weather can be -40℃ -50℃, so we use special cold-resistant PVC housing to ensure the long-term use of the High voltage AC220V IP67 outdoor LED strip lights.

Types of High voltage AC220V IP67 outdoor LED strip lights

Latest constant current high volt driver-free LED strip lights

With the rapid development of LED drivers and integrated circuits, high-voltage LED strips have taken high-voltage constant current driver-free IC. With the help of which the high-voltage light strip becomes much more stable. Even in the case of unstable utility power supply, it can ensure the normal operation of the LED strip. Moreover, the emergence of high-voltage LED lamp beads has little pressure drop , which can also make high-voltage light strips not limited to one meter and one cut. Now there are also 10cm cut high-pressure light strips.

Normal model

Suitable for ordinary household, commercial, or decorative use.economical and practical

Engineering model

With iron frame for easy transportation,suitable for dams, mine tunnel, shaft, tunnel, river cross harbor tunnel, subway excavation of underground works .

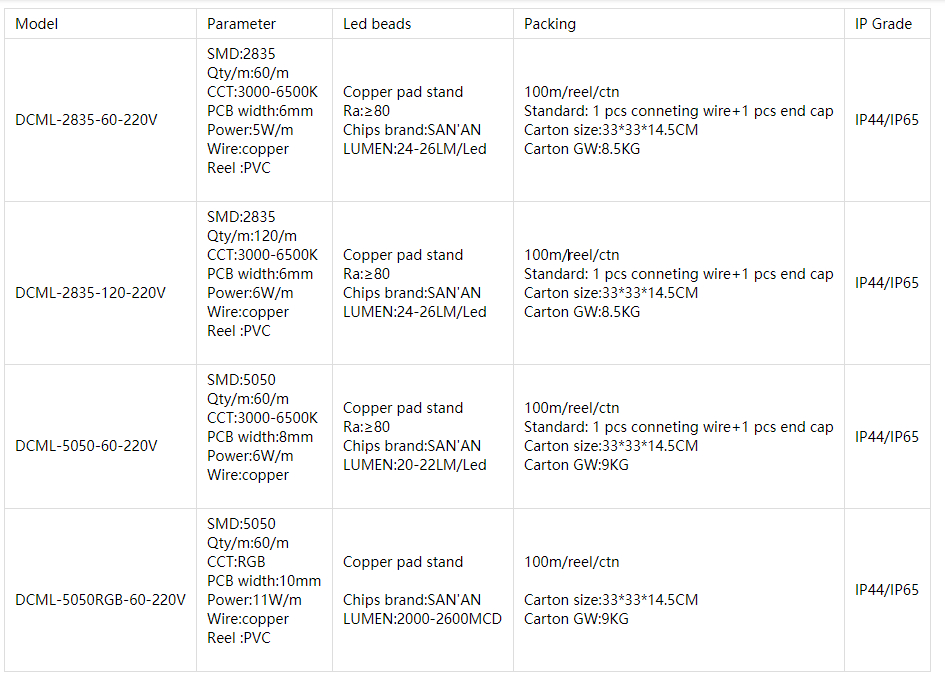

PARAMETERS LIST

Good points of High voltage AC220V IP67 outdoor LED strip lights:

Wide range of choices: there are a variety of specifications and models available ,brightness or function is free to choose.

Cheap cost: It can save the cost of power supply and controller, low material cost

Convenient installation: it is what the electrician or operator like most. Simple composition, easy to install. Low labor costs

Bad points :

Strobe is a common fault, but can be adapted to the constant current driver or constant current IC

Installation is not easy to standardize, which resulting in uneven light output or serrated light spots

Somewhere need accurate cutting, but the length is not enough, or folded up to use, the brightness is not uniform, also easy to cause the danger of burning out.

Color temperature drift.Because of the performance of transparent PVC housing, it will affect the attenuation of the strip light,as well as the CCT, namely the color temperature drift. In general, it will get 200-300K floats higher than actual level. For example: we use 2700K lamp beads to make the strip light, but finally we get maybe 3000K when finished.

Although it is easy for install, but because of the direct access to the utility power, without the protection of driver , therefore, the strip is easily get damaged due to some surge current or peak voltage

Quality level mixed in the market. It is easy to buy those poor quality such as thin PCB, low brightness light beads, iron or aluminum wires.

How to tell the high end High voltage AC220V IP67 outdoor LED strip lights?

We should judge it through below points:

1.Good quality lamp beads, resistance, and thicker copper plate of PCB.

2.Using pure copper wire with larger cross section . Try to avoid those copper-coated aluminum, or even aluminum, iron wire.

3.Encapsulation material should be good and of high transparency, soft, uniform sealing, no peculiar smell.

4.Choosing the power supply plug which built-in larger chip. It can easily prevent the damage to lamp beads. Because bridge stacks have current limits, such as 4A, 6A, it is easy to overflow and lead to burn out in the case of small IC used

Precautions for construction of High voltage AC220V IP67 outdoor LED strip lights

1. All the works should be finished by the qualified technician or operator.

2. Pay much more attention on the high volt problem. Avoid those conductive parts when install the AC 220V strip light.

3.Try not to fold the light strip repeatedly. Folding the light strip will not only affect its heat dissipation, but also easily make it deformed, or some falling off of solder which will lead to the “dead bead” problem.

Welcome to consult DELIKAY High voltage AC220V IP67 outdoor LED strip lights !

OEM customized service &Turn-key solution available!